Hi all, my name is Arlene Daley and I am an author and historian who loves to share my knowledge of Arizona's past with people. In this article I would...

About the state

Arizona is a state of great canyons

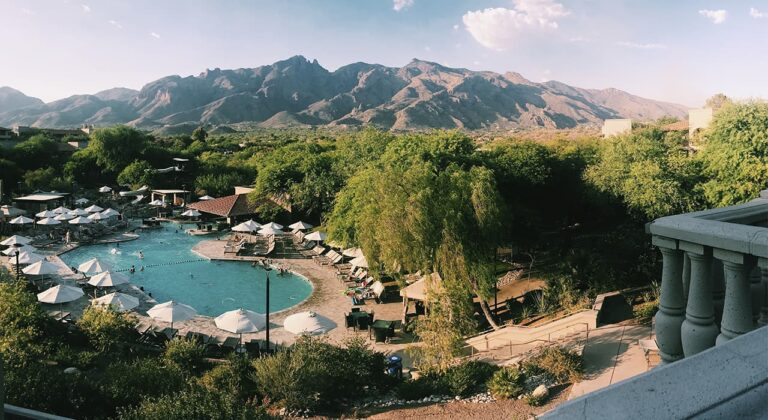

Arizona became the 48th state in the United States when it joined the Union on February 14, 1912, and is one of the most recognizable...

Cities in Arizona

The state capital surprises with numerous places of interest. Fans of original architecture will appreciate the city's 20-story City Hall made of metal and glass

Attractions in Arizona

A deep crevasse winds through the state of Arizona for more than four hundred kilometers. The Canyon owes its appearance to two rivers

City histories

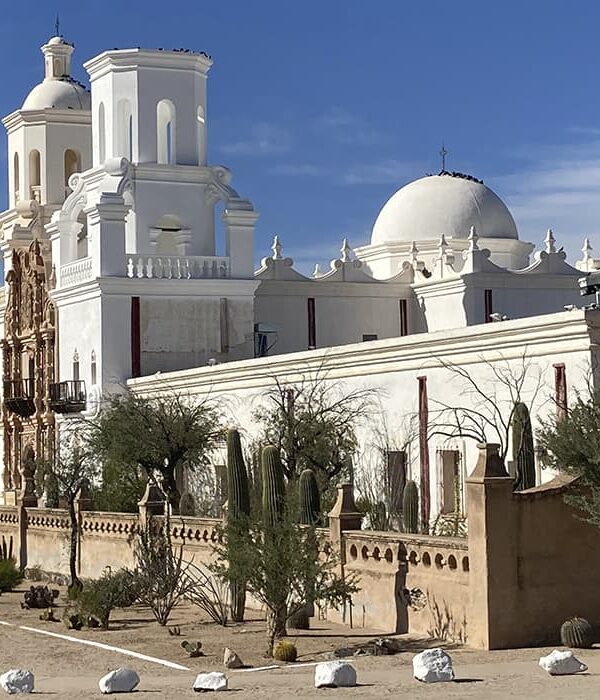

The Influence of Spanish Colonial Design on Arizona’s Interior Spaces

When you think of Arizona, what probably comes to mind are vast deserts, towering saguaro cacti, and picturesque sunsets. But beyond its natural beauty, Arizona […]

Arizona’s Rich History and Vibrant Present

Arizona, a state with a diverse and captivating history, holds a unique place in the tapestry of American heritage. From the early Native American inhabitants […]

City of Mesa

A south-eastern suburb of Phoenix, Mesa was founded by Mormons who used the ancient Hohokam canals for irrigation.

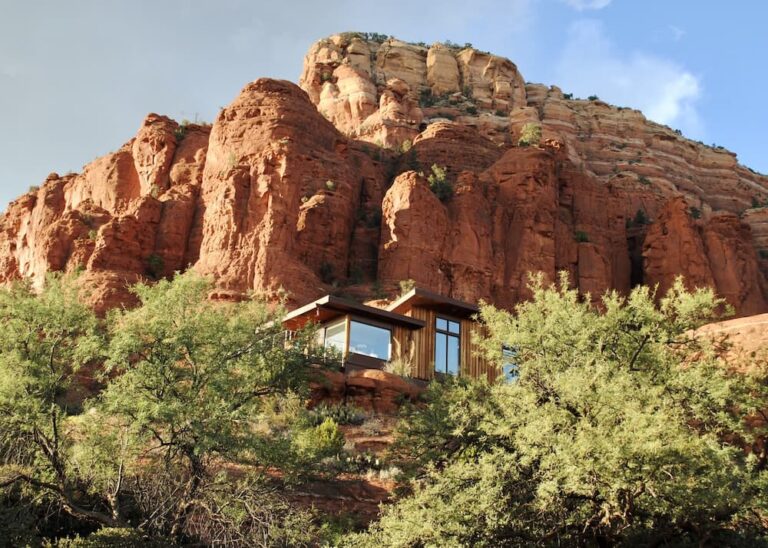

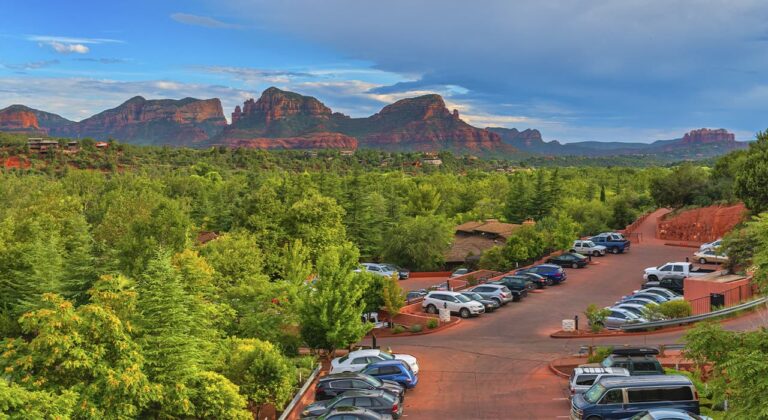

Sedona is the best city in Arizona

Sedona is a small town in northern Arizona in the US, a real oasis in the desert lands at the very edge of the Colorado Plateau

Tempe is a town in Maricopa County

Tempe is a city in Maricopa County, Arizona, USA, where the Census Bureau reports a population of 180,587 in 2020.

Yuma is a city in the far south-west

Yuma is a city and the administrative centre of Yuma County, Arizona, USA. The city had a population of 93,064 in the 2010 census, up from 77,515 in the 2000 census.